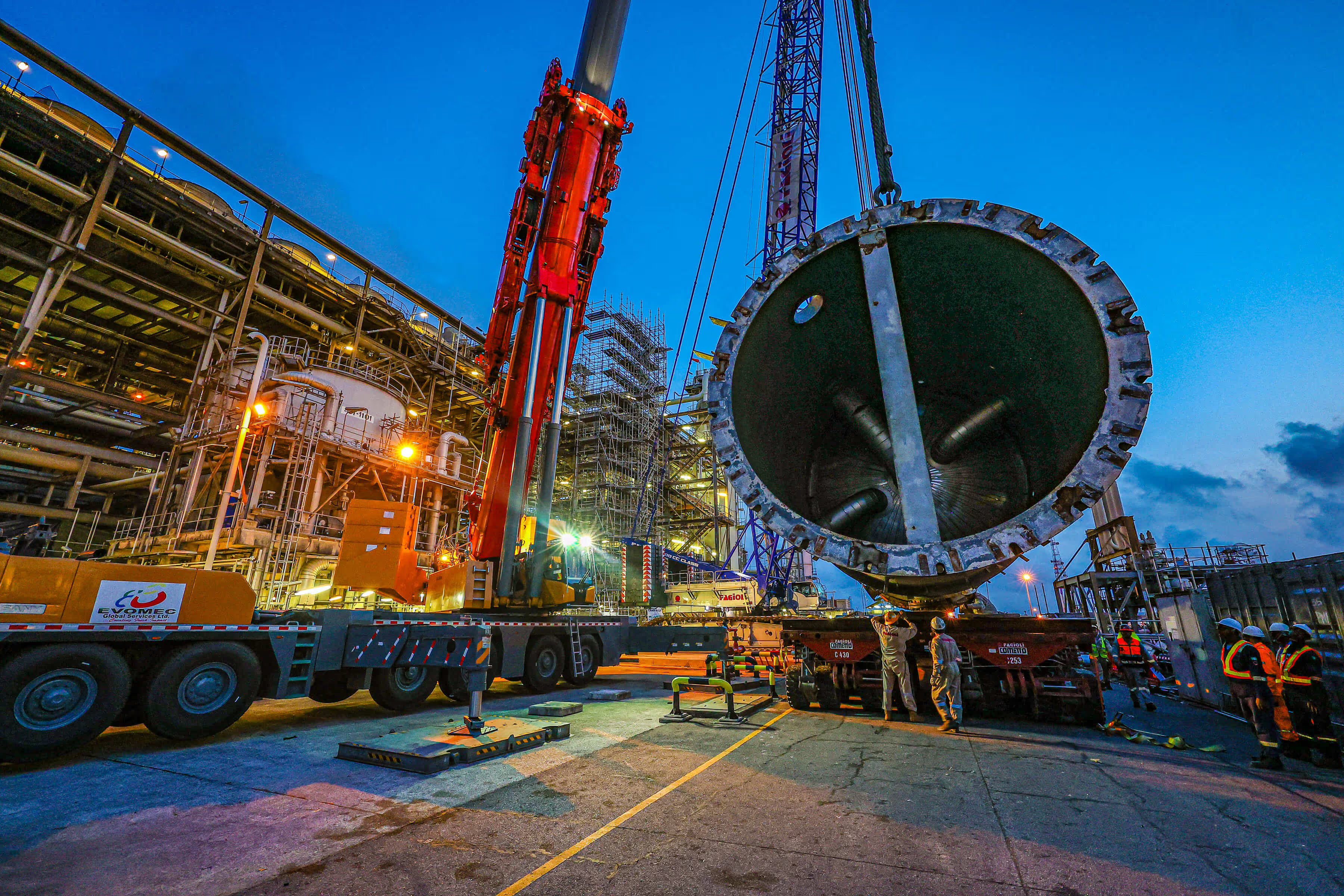

Production Plant

Our six-train production plant is the engine of NLNG’s operations in Nigeria. Since 1999, the plant has grown in capacity, increasing output and maintaining world-class operational standards in the delivery of sustainable energy.

Spanning 2.27 square kilometres on Bonny Island, our plant is a global benchmark for efficiency and performance.